EQUIPMENTS

Integrated Optical Glass Manufacturing Capabilities

Our production facility integrates multi-chamber AR/AG/AF coating systems, high-accuracy CNC machining centers, automated silk-screen printing lines, and controlled-profile tempering furnaces, forming a complete in-house manufacturing chain for advanced optical glass. This end-to-end capability allows us to execute every critical step—from optical coating, contour shaping, multi-aperture drilling, decorative printing, edge detailing, to final strengthening—with full control over quality, precision, and production stability.

With this infrastructure, we consistently achieve optical-grade surface performance, micron-level dimensional accuracy, uniform coating adhesion, and reliable mechanical strength across complex geometries and customized structures. Our equipment supports diverse applications including AR/AG/AF functional coatings, precision apertures, device windows, sensor interfaces, and high-strength display components.

By combining advanced equipment with a standardized production workflow, we provide dependable manufacturing for demanding sectors such as display technology, industrial control systems, smart appliances, automotive interfaces, and professional instrumentation—ensuring rapid prototyping, stable mass production, and long-term consistency under strict international requirements.

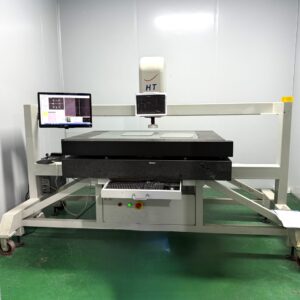

Large-Format Precision Laser Machining

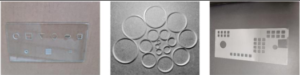

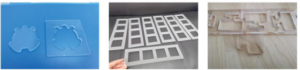

Our 2500 × 1500 mm laser machining system is designed for high-accuracy processing of optical-grade glass. The platform supports a thickness range of 0.3–30 mm, with micro-aperture drilling capability down to 0.1 mm, and maintains dimensional tolerance within ±0.05 mm under continuous operation.

The system enables precise contour cutting, multi-hole drilling, edge detailing, and inner/outer profile machining for both standard and non-standard geometries. Its stability and repeatability make it suitable for engineering applications requiring controlled tolerances, complex structural layouts, and rapid design iteration.

Typical outputs include functional apertures, optical windows, circular and slotted parts, structured patterns, and other customized geometries used in display assemblies, industrial control modules, sensor housings, and optical instrumentation.

Advanced Optical Glass Manufacturing Capabilities

Integrated Coating, Strengthening, and Precision Processing

Core Optical Coating Systems (AR / AG / AF)

Our multi-chamber vacuum coating systems are engineered for high-uniformity AR, AG, and AF functional coatings, providing precise control over reflectance, color-neutral transmission, and coating adhesion across chemically and thermally processed optical glass substrates.

Optical Glass Tempering & Mechanical Strengthening

Our precision tempering furnaces provide controlled thermal strengthening for optical glass, ensuring high mechanical durability while maintaining dimensional stability and surface integrity after coating and machining processes.

Quality Control & Inspection

Quality control is embedded at each critical production stage, including coating, machining, strengthening, and assembly. Optical inspection, dimensional verification, and process validation are performed to ensure optical performance, coating reliability, surface integrity, and dimensional consistency, supporting repeatable results for both sample development and volume manufacturing.

Application Focus